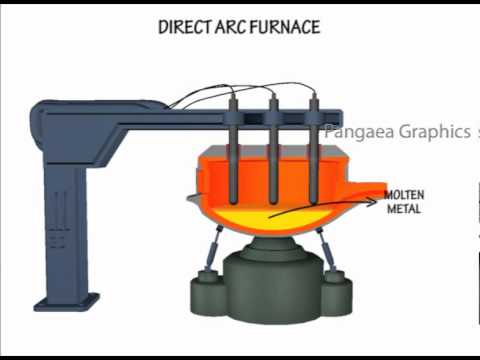

Direct Arc Furnace

It could be either of

conducting-bottom type [Fig. 47.12 (a)] or non-conducting bottom

type [Fig. 47.12 (b)].

As seen from Fig. 47.12 (a), bottom of the furnace forms part of the electric circuit so that current passes through the body of the charge which offers very low resistance. Hence, it is possible

to obtain high temperatures in such

furnaces. Moreover, it produces uniform heating of charge without stirring it

mechanically. In Fig. 47.12 (b), no current passes through

the body of the furnace.

Most common application

of these furnaces is in the production of steel because of the ease with which

the composition of the final product can be controlled during refining.

Most of the furnaces in

general use are of non-conducting bottom type due to insulation problem faced

in case of conducting bottom.

Hence, such furnaces

have to be rocked continuously in order to distribute heat uniformly by

exposing different layers of the charge to the heat of the arc. An electric

motor is used to operate suitable grinders and rollers to impart rocking motion

to the furnace. Rocking action provides not only thorough mixing of the charge,

it also increases the furnace efficiency in addition to increasing the life of

the refractory lining material. Since in this furnace, charge is heated by

radiation only, its temperature is lower than that obtainable in a direct arc

furnace. Such furnaces are mainly used for melting nonferrous metals although

they can be used in iron foundaries where small quantities

of

iron are required frequently.

Related Articles

Lesson meta keywords and meta description:

Write a public review