Stepper motors

General information on stepper motors

Stepper

motors are special versions of the synchronous machine, in which the rotor is a

permanent magnet, while the stator consists of a coil package. In contrast to

synchronous motors, stepper motors have a large number of pole pairs. Motor

operation requires a control unit, which energises the individual motor

windings based on a certain pulse sequence. A stepper motor has a tendency to

mechanical oscillation. Above its load limit it loses dynamic characteristics

and may lose individual steps. Under high load the shaft may even stop. Safe

positioning is therefore only guaranteed within the performance limits. If the

motor is operated within its load limits, positioning without feedback of the

rotor position can be achieved by linking individual steps. This operating mode

(open loop control) and the durability of the stepper motor enable it to be

used as a positioning drive in price-sensitive applications.

Basic function principles of a stepper motor

Like most electric motors, a stepper motor consists of a stator (fixed external winding) and a rotor (rotating shaft with magnets).

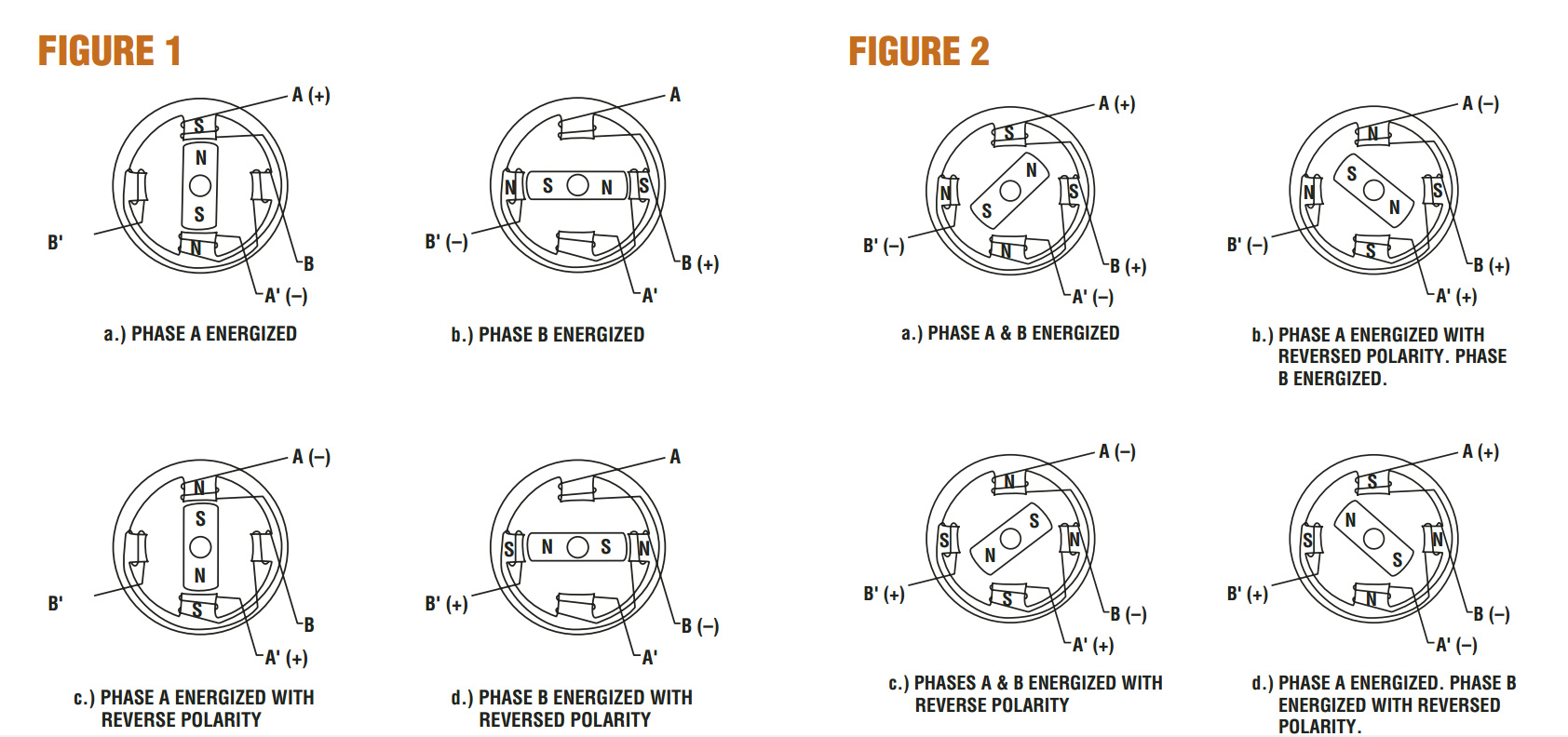

The rotation of the motor shaft (rotor) is generated by rapid energising the

electromagnetic field of the stator, causing the shaft to turn by the step

angle a. In a minimum control configuration, the stepper motor is moved from

pole to pole, or from step to step. A full turn of the motor shaft is therefore

made up of individual steps. Energising of the motor windings results in a magnetic field in the motor from north

to south (or south to north if the power supply has negative polarity and the

winding is arranged accordingly). The movable stator with its permanent magnets

aligns itself according to the direction of the external magnetic field of the

stator.

A special type of

synchronous motor which is designed to rotate a specific number of degrees for

every o electric pulse received by its control unit. Typical steps are 7.5 or

15 per pulse. It is a motor that can rotate in both directions, move in precise

angular increments, sustain a holding torque at zero speed, and be controlled

with digital circuits. It moves in accurate angular increments known as steps,

in response to the application of digital pulses to the electric drive circuit.

Generally, such motors are manufactured with steps per

revolution. Step motors are either bipolar, requiring two power sources or uni

polar requiring only one power source.

Θm =2/p*θe

wm =2/p*we

Related Articles

Lesson meta keywords and meta description:

Write a public review